ABOUT ADL MANUFACTURING

At ADL, our goal is to meet or exceed all metrics of successful PCB assembly and to employ vigorous standards of lean manufacturing. With an in-house business manager and manufacturing engineer assigned to each customer, you receive personalized and attentive service. We are committed to providing state-of-the-art capabilities and sophisticated testing processes so you can deliver the best version of your product to market.

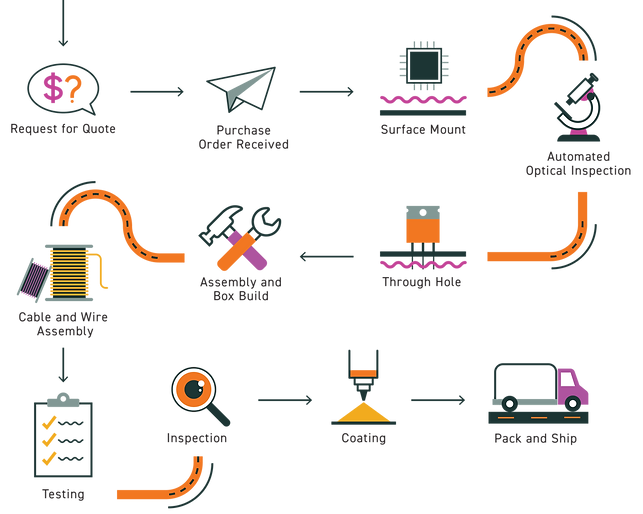

OUR MANUFACTURING PROCESS

This is a typical process map; there is variation in the process depending on the customer requirements.

ENVIRONMENTAL CONSCIOUSNESS

We strive to be a responsible member of our local community by incorporating sound environmental practices into our day-to-day business operations. Our programs include lead containment, electronics recycling and reusable packaging. We continuously strive to minimize waste, prevent pollution and minimize health and safety risks in all our operations.

ASSEMBLY SERVICES

Surface Mount Assembly

-

Prototype, low, medium, high volume

-

RoHS Compliant Production Capabilities

-

LED assemblies, Fine Pitch, BGA,

uBGA, QFN, 0201 components -

Pemtron 3D solder paste inspection

Through Hole Assembly

-

Automated and manual processes

-

Prototype, low and medium volume

Box Build and Control Panel Assembly

Cable and Wire Harness Assemblies

Potting and Coating

-

Two-part epoxies

-

Silicone dips

Testing and Inspection

-

Custom test fixture design

Field Return Repair Service

-

Troubleshooting to the component level

EQUIPMENT

Surface Mount Technology (SMT)

-

4 identical, fully automated lines

-

MPM Accela screen printers with post-print 2D inspection

-

Pemtron 3D solder paste inspection capabilities

-

Universal Fuzion placement machines

-

NPI barcode scanning for machine and component setup and validation

-

Capable of placing 0201 components and 0.4mm BGAs

-

BTU Pyramax 150 12 zone reflow ovens with auto load/unload functionality

Through Hole Technology

-

Fully automated insertion equipment - RAD_8 radial machine and VCD_8 axial machine

-

Auto and manual component lead prep

-

Slide lines and "one piece flow" lines

-

Hand-soldering stations

Wave and Selective Solder Technology

-

RoHS compliant production capabilities

-

Two Electrovert Vectra wave solder machines, one for leaded assemblies and one for lead-free

-

ERSA 345 selective solder machine with dual alloy capability - no changeover required

Inspection

-

Three YESTECH FX AOI machines

-

X-ray capability

-

End of line quality inspection

Rework

-

Air-Vac semi-automated rework equipment

-

Technicians certified to IPC-A-610 and IPC-A-620

Potting and Coating

-

PVA for automated conformal coating

-

Two enclosed, vented spray booths

Wire Processing

-

Komax KAPA240 wire cutter/stripper

-

Artos CR-22 and CS-326 wire processing equipment

-

Dynalab 256-point cable harness tester

-

Schleuniger and Carpenter processing equipment

Aegis Manufacturing Software

-

Directly imports PCB design files (CAD ASCII, Gerber, X-Y Data and scanned image formats)

-

Timely turnaround for offline multi-machine programming

TESTING AND INSPECTION

Automated Optical Inspection

-

No tooling needed

-

Ensures good part placement and good solder fillets

Test Engineering

-

Custom test procedure and fixture design

-

LabView for automated testing

-

Data collection and serialization

-

In-line firmware programming

-

Experienced test technicians on staff

-

Use existing procedures or let us create one

Agilent 3070 for In-circuit Testing

-

The most accurate and highest performing in-circuit tester available

-

Without power: checks for opens, shorts and components values

-

With power: checks functionality of digital/analog circuit elements and blocks of components

-

JTAG and boundary scan support

Our goal is to be a reliable, flexible asset to our customers while building long-lasting partnerships. We can customize our services to better serve you. Our specialties include:

ADL TECHNOLOGY LLC

2727 Scioto Parkway, Columbus, OH 43221

(614) 345-9040

HOW TO GET A QUOTE

Inquiries may be sent to adl.sales@lsi-industries.com. To quote your assembly, we will typically ask you to provide the following documentation:

1

2

3

4

5

6

Bill of materials: reference designators, component manufacturers, part numbers and substitution allowance

Gerber files: describe each PCB layer; used by the PCB fabricator to build the bare circuit board

Fabrication notes: type of circuit board material, leaded or lead-free, and other special instructions for the circuit board

Testing instructions: any necessary procedures,

fixtures or other required equipment

Timing and quantity: estimated annual usage (EAU) and the desired product delivery schedule

Other documentation: assembly drawings, electrical schematics, ASCII-formatted PCB layout files, etc.

TERMS OF SALE